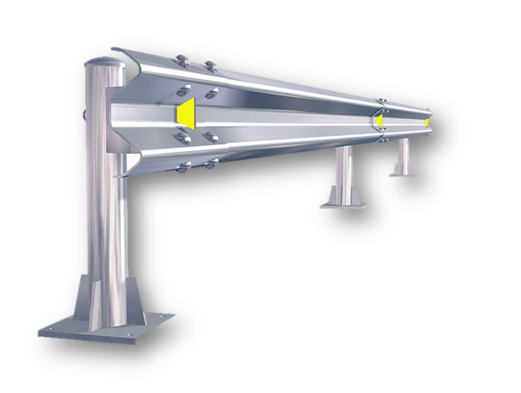

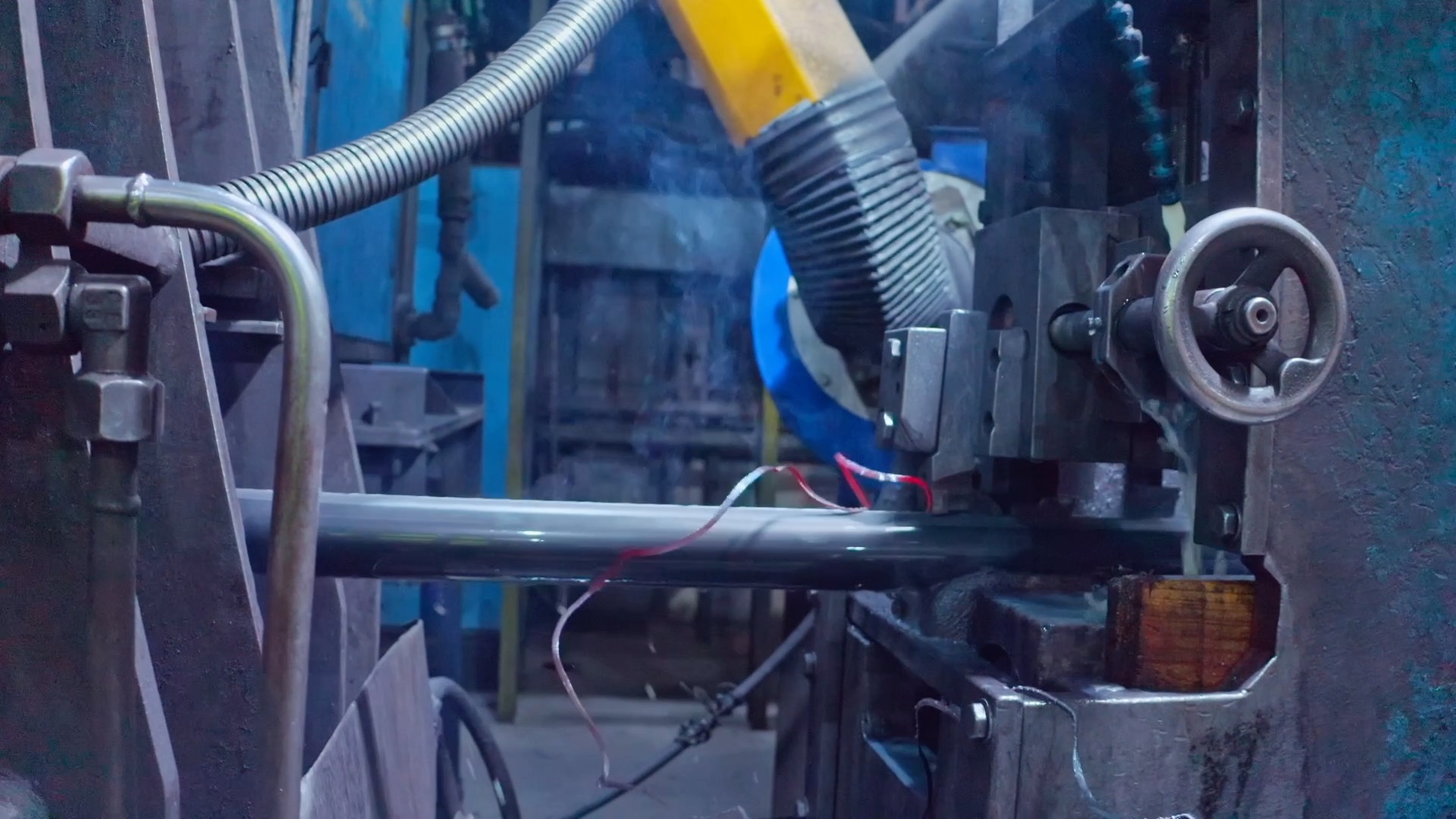

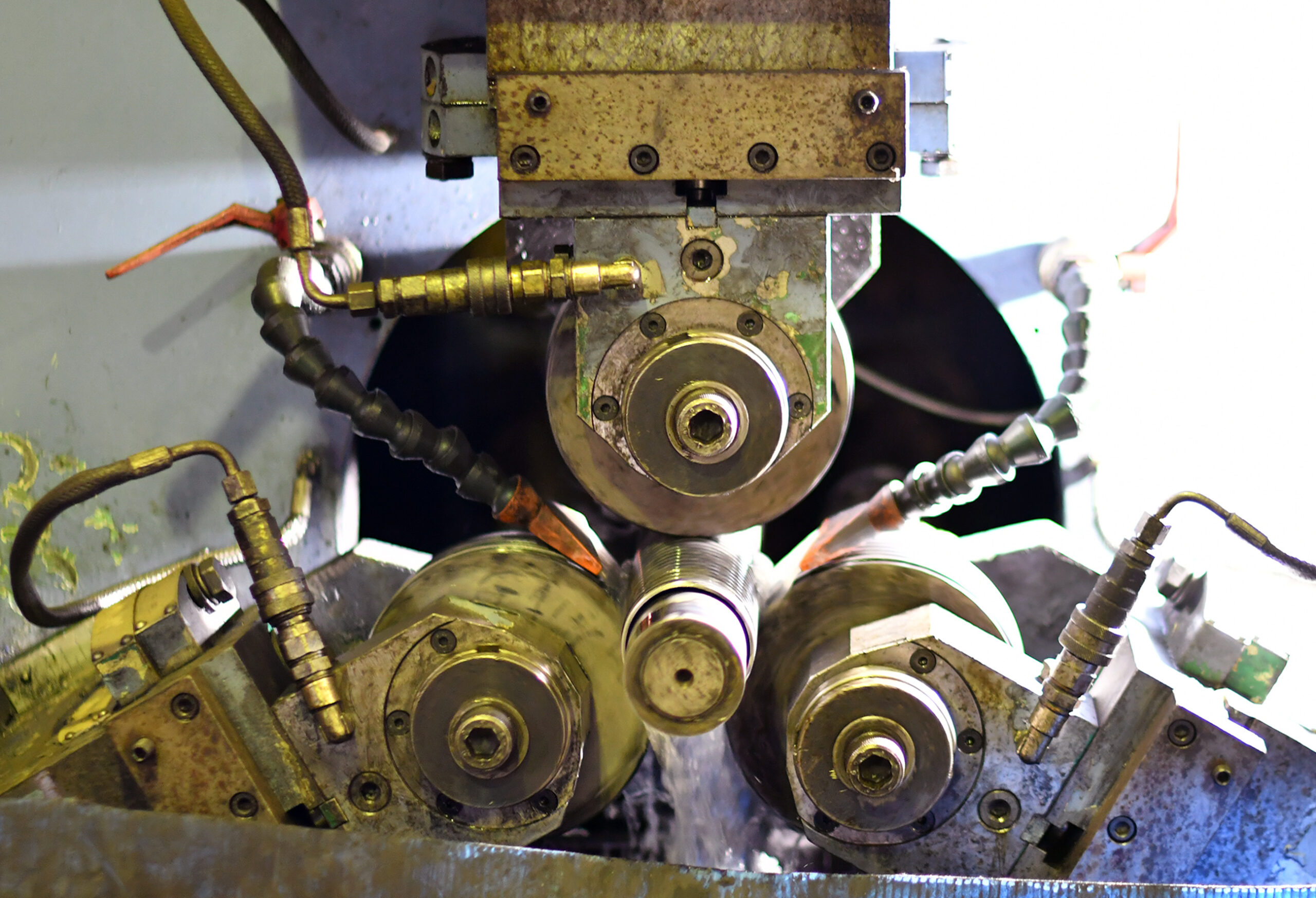

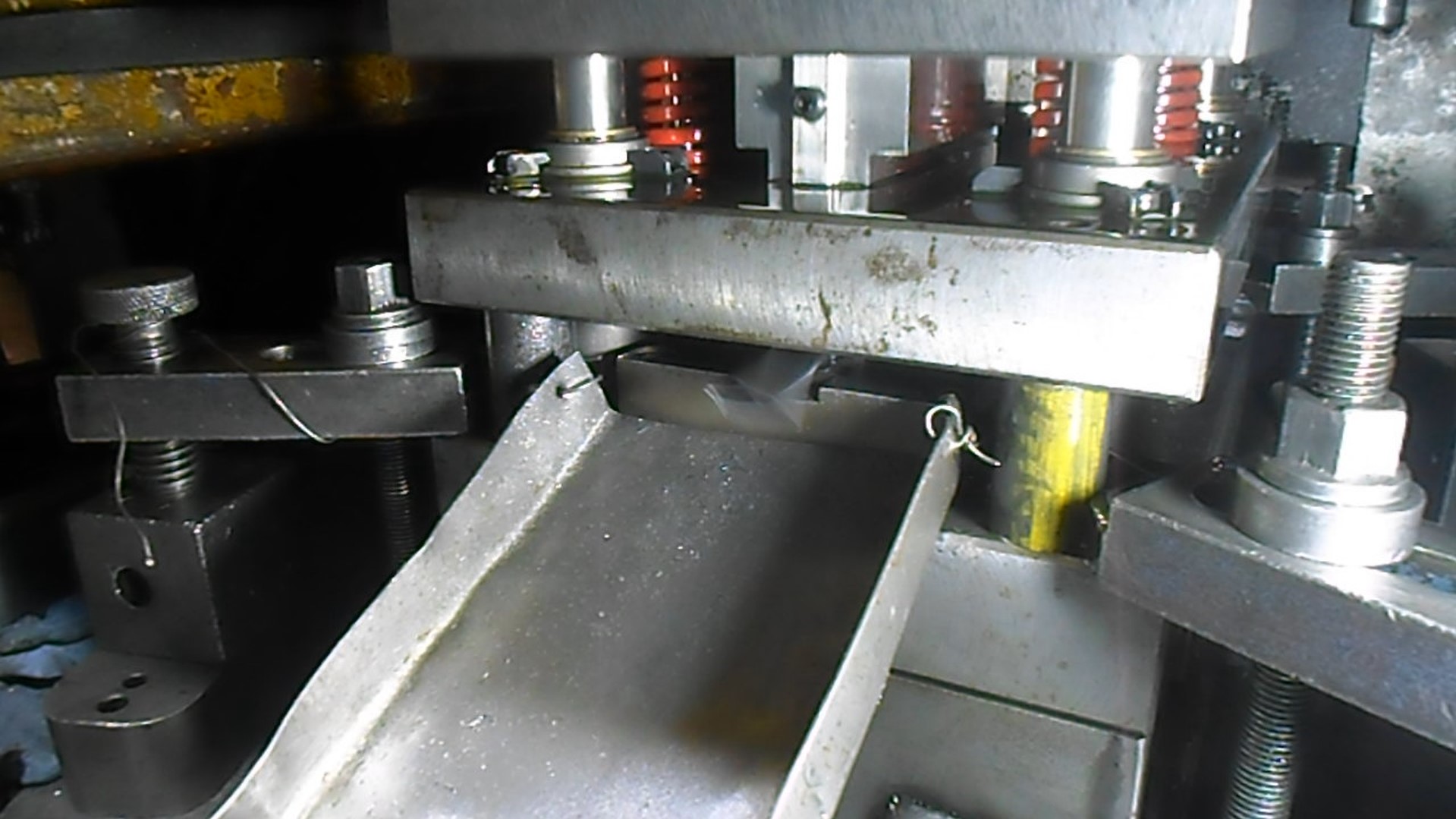

Bending service for steel tubes respecting the defined angle and bending radius requirements.

- Material quality: Steel and stainless steel

- Round Section: between Ø13mm and Ø50mm Max

- Prismatic section ≤ 50mm x 50mm

- Wall thickness: 4mm Max

- Tube length: 250mm min to 5000mm Max

- Mandarin