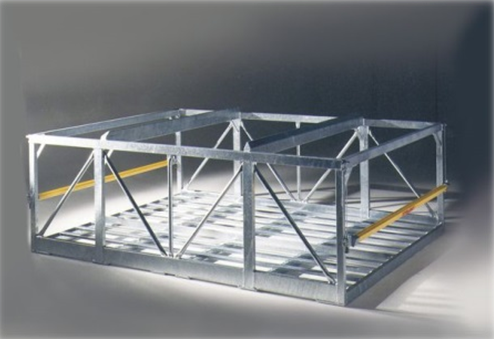

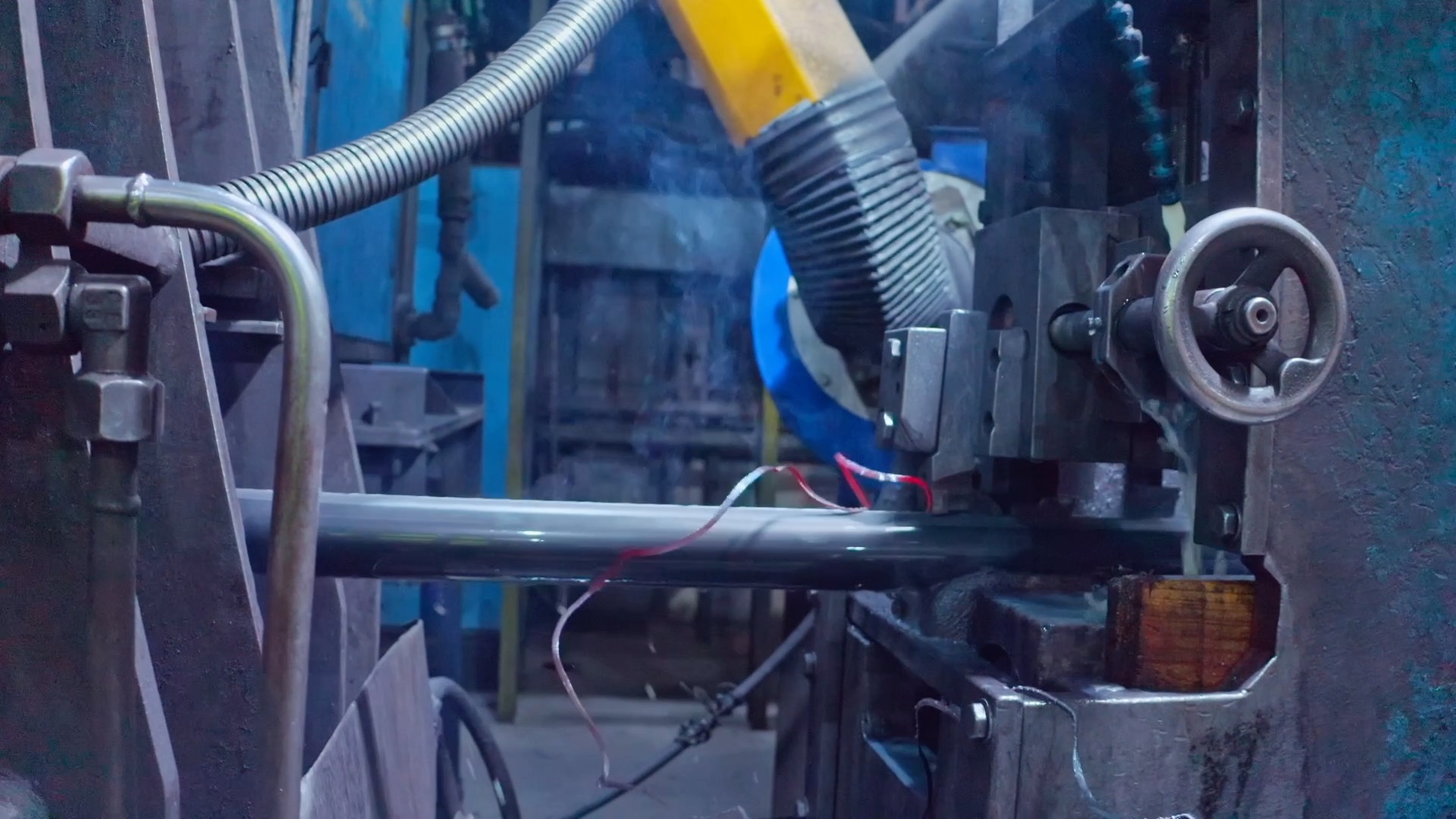

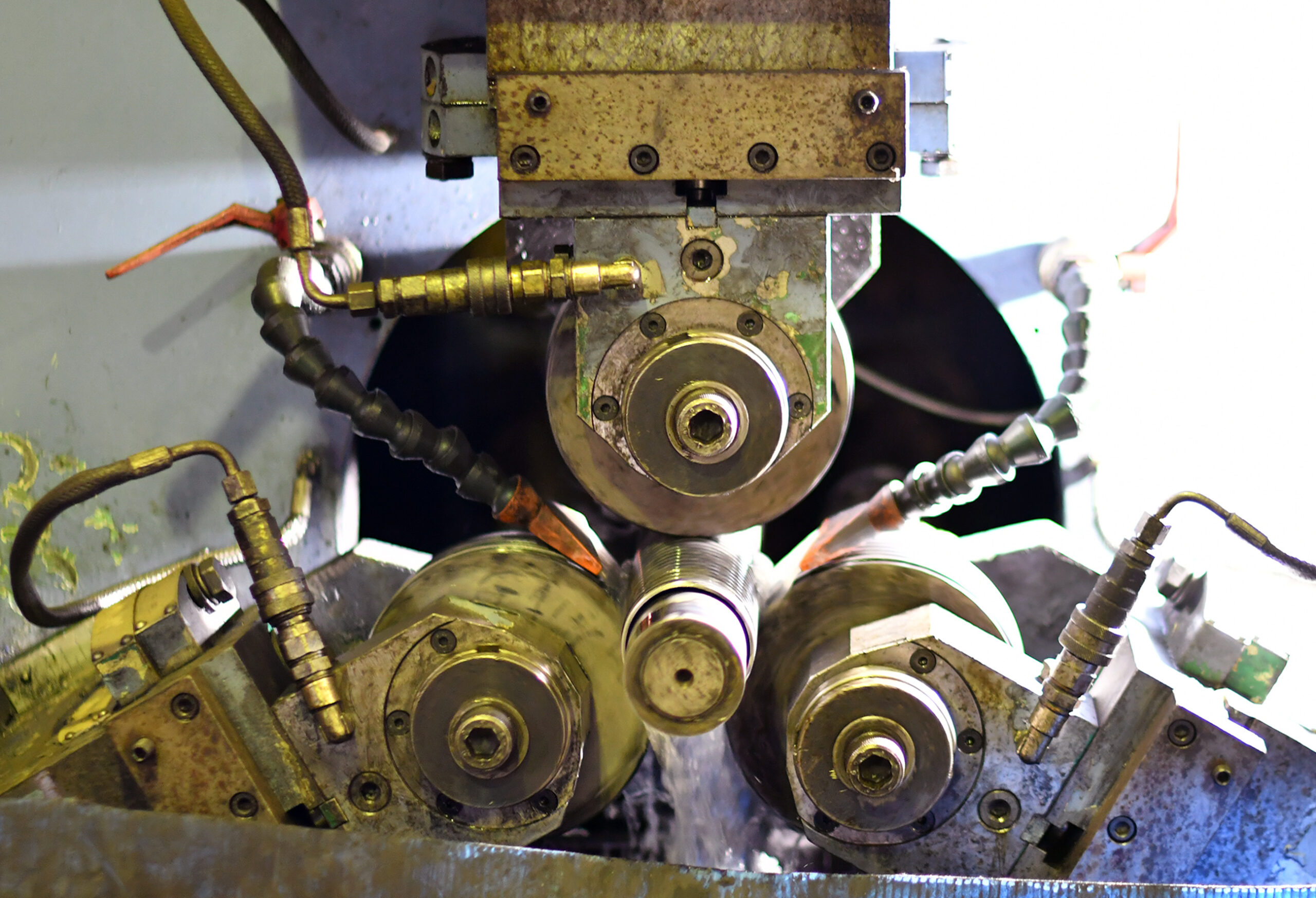

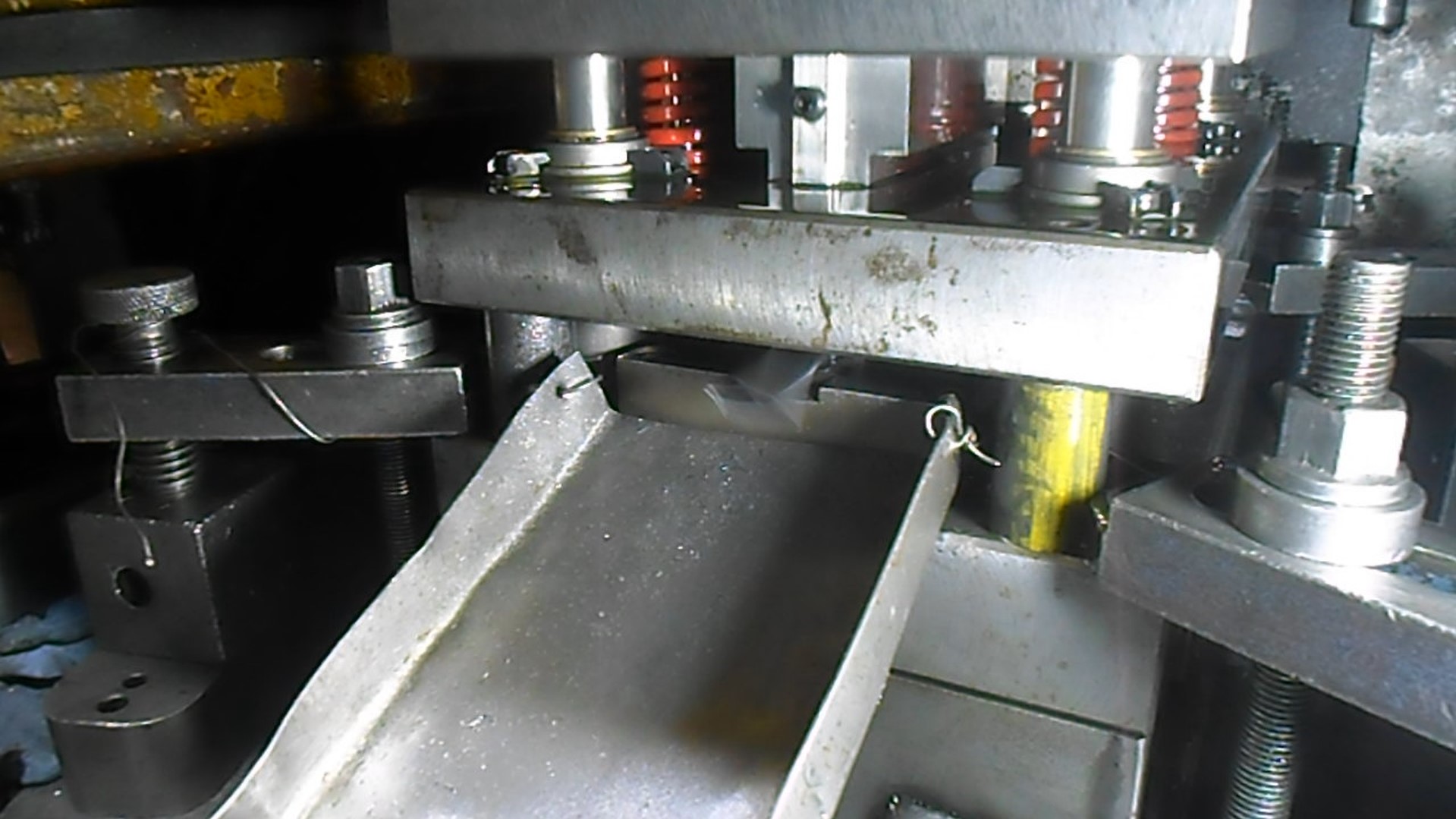

- General Industrial Framework

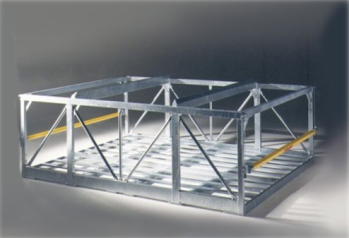

- Logistic Warehouse Framework

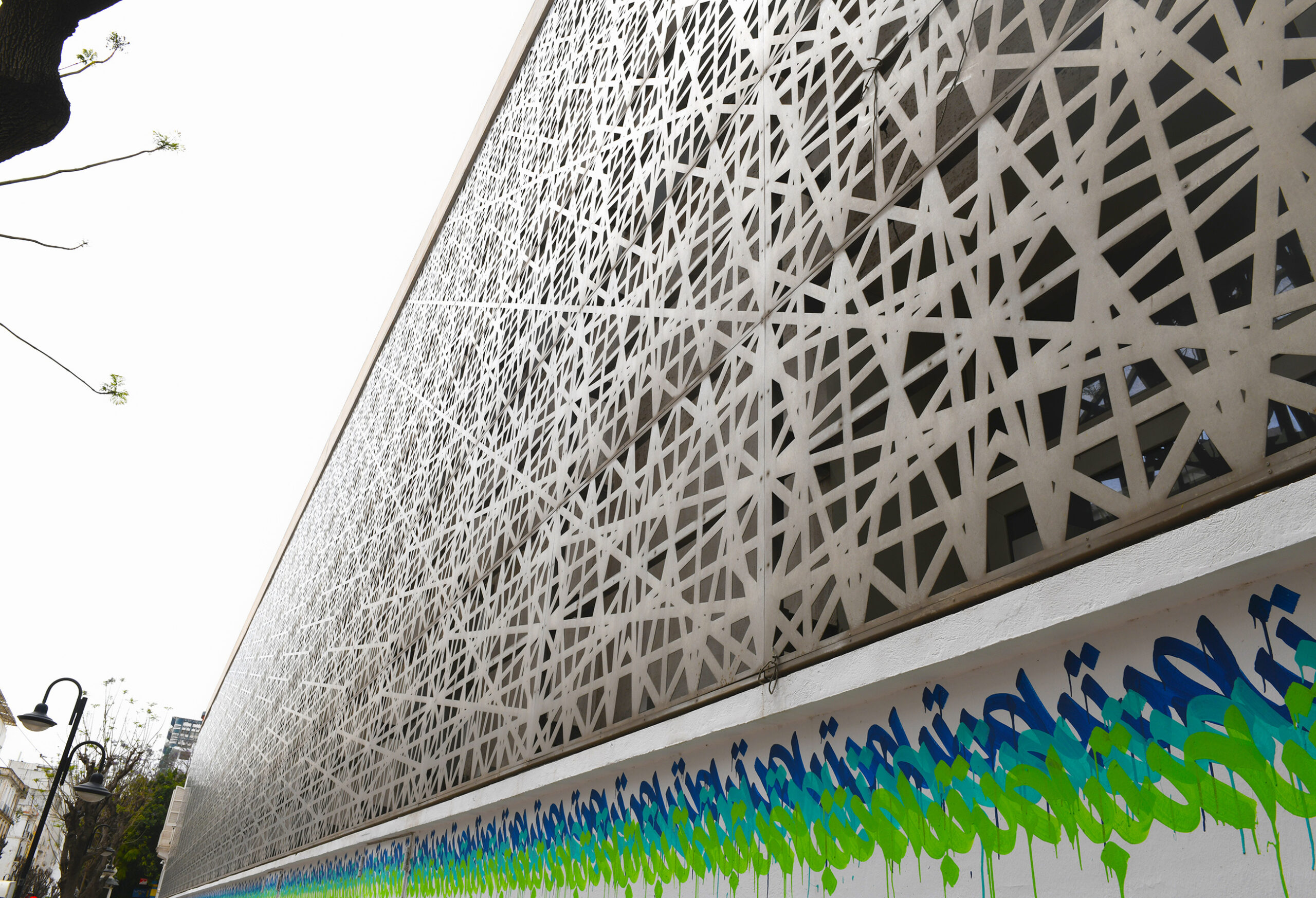

- Malls & Retails Building

- Prefabricated Housing

- FMCG Mills

- Electronic, Chemical and pharmaceutical factories

- Tertiary Building

- Economical collective Real Estate

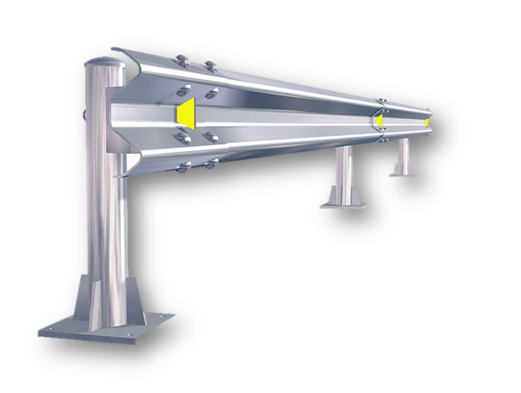

- Bridge, footbridge and viaduct: works of art made of metal

- Energy, Marine and river facilities

- Transport Hangars, Stations and Tunnels